[ad_1]

“Cooler than Cool Roofs: How Heat Doesn’t Move Through a Green Roof”

“Cooler than Cool Roofs: How Heat Doesn’t Move Through a Green Roof” is the 7-part Green Roof Energy Series explaining the key aspects of green roof heat transfer issues and the best ways to take advantage of a green roof’s energy benefits by Greenroofs.com collaborator Chris Wark.

Green Roof Energy Series Part 5: Assuming Insulation

By Chris Wark, Energy Editor – Originally posted November 29, 2010

You may ask, “How well does a green roof insulate a building?” “What is the R-value of a green roof?” “More insulation is better, right?” “Does a green roof system have to include insulation?” “Don’t engineers already figure this out for us?”

You sure ask a lot of questions about insulation, so I suppose it is time to address each one:

“How well does a green roof insulate a building?”

The ability of a green roof to help keep a building cool during the summer and warm in the winter depends on the design and location of the building, as well as the type and construction of the green roof.

Most of the green roof heat management happens right at the surface. Images: cleens.com

Note that the previous sentence does not include the word “insulate” but does contain the word “depends.” In fact, understanding how to rate the ability of a green roof to manage heat energy has as much to do with language as it does with learning heat transfer. In order to make sure we are all clear on how insulation works, particularly in a green roof system, we need to take a little journey through the lexicon of insulation terminology, starting with:

“What is the R-value of a green roof?”

The most common request I get from architects and engineers is for the R-value of a green roof system. Unfortunately, the ability of a green roof to control the flow of heat energy cannot and should not be described only by an R-value, not even an “adjusted,” “equivalent,” or “approximate” R-value.

The term “R-value” has a very specific meaning. The “R” stands for resistance, as in thermal resistance. Physically, this describes nothing other than a simple restriction to heat flow, regardless of direction, which is one of the less-significant thermal properties of vegetation and its media and drain layer.

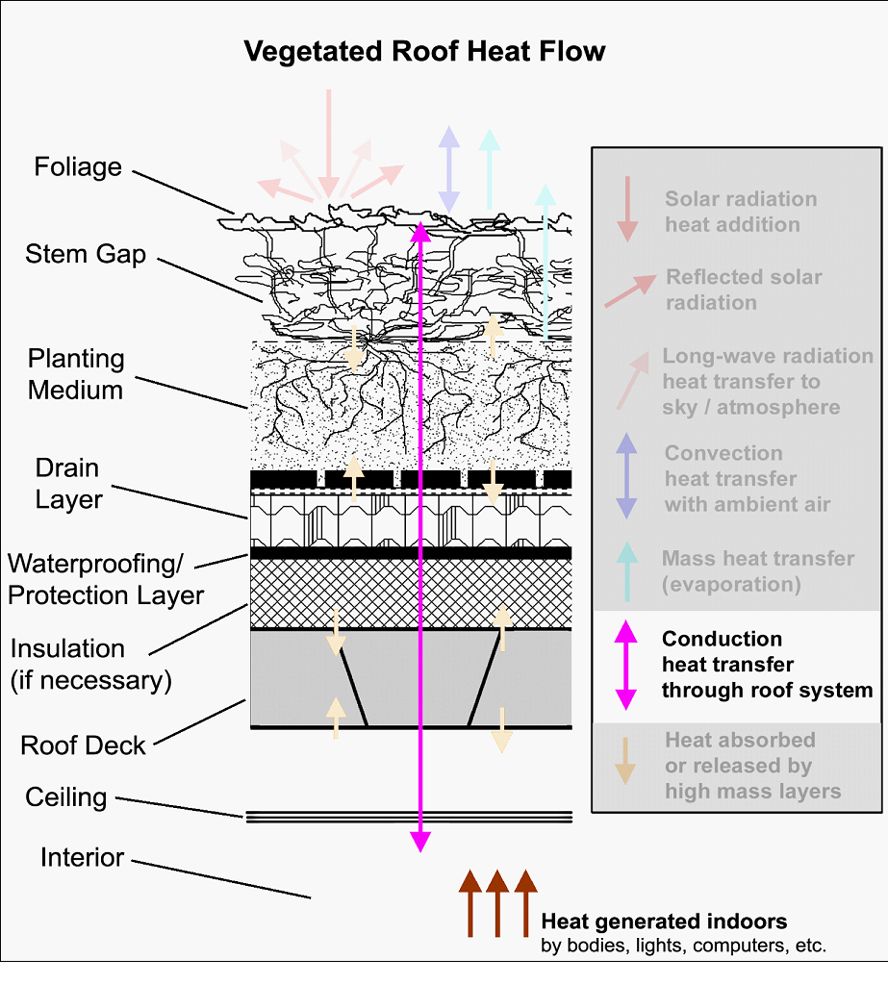

So far in this series, I have described a number of ways that different elements of a green roof manage heat along with simple resistance to heat conduction – evaporation, reflection, convection, and thermal mass (see Part 1 of this series). Like an R-value, each of these has its own “value,” “coefficient,” or “dimensionless number” associated with equations that describe how they affect heat flow. They are beyond the scope of this article since some are Greek letters that are difficult to type.

Copyright 2010 Christopher Wark

Mathematically, the heat conduction equation that properly uses an R-value is also very simple, whereas the equations that describe energy transfer through evaporation, reflection, convection, and thermal mass can get ugly. Unfortunately, plants and soil don’t care about math. They insist on constantly adapting to their environment in complex, directional ways that can only be described using a combination of the nastier mathematical methods and formulas.

A green roof does not just sit there resisting heat flow, it is an active energy device, literally collecting, processing, and releasing energy according to its immediate need, just like all other living things, including people. Now for a good rhetorical question: What is the R-value of a human?

“More insulation is better, right?”

It depends. Unlike vegetation, regular old foam, batt, or cellulose insulation does actually just sit there resisting heat flow. It is wonderful at slowing down heat loss during winter but that is not necessarily enough reason to rely on it exclusively throughout the year.

For example, let’s say a lot of heat is already being generated inside a building by people, lights, computers, copiers, etc. (it is easier than you think). That internal heat generation might be useful in January in Minneapolis but during spring, autumn, and even summer nights, it works best to let that heat escape, which can be accomplished with designs that utilize less insulation. As I have learned from whole-building energy and CFD modeling, much more insulation than necessary is often installed in many buildings located in milder climates.

FloVENT CFD temperature and air flow profiles for a typical office area.

“Does a green roof system have to include insulation?”

It depends. Since most of the green roof heat management happens right at the surface – in the vegetation and the planting media – any additional energy conservation measures that go underneath the drain layer should supplement the vegetation/media heat management, not the other way around. Also keeping in mind that heat flows in both directions, the amount of insulation you might put under your green roof should be calculated for your specific building and location before assuming how much is necessary, if any.

So the short answer to your question is: of course not – unless, of course, your local government tells you that it must (and how much).

Image: InterNACHI

“Don’t engineers already figure this out for us?”

Since every building is unique and the energy effectiveness of any green roof is totally dependent on the building’s design and location, the energy savings associated with a green roof can only be determined as part of a whole-building energy model – the kind typically needed for LEED™ certification.

eQUEST© (DOE-2.2) output

Commercial building owners have 2 choices:

1. Hire an energy analyst who actually understands green roof thermal properties to model the building and conduct a proper roof treatment study, or

2. Simply guess at how much the roof system design will affect energy use.

For a typical home, building codes usually already dictate the amount of insulation required. However, for a project such as a 50,000 square foot low-rise office building in St. Louis, guessing could be a $200,000 gamble; but gambling is fun, right?

Green roofs are not the only roof treatment that cannot be described by an R-value and whose energy performance is highly dependent on location. To a certain extent, “cool” roofs suffer a similar lack of thermal simplicity. We will take a look at those similarities and a couple important differences next month.

Copyright 2010 Christopher Wark

~ Chris Wark

References:

1. Incropera, Frank and DeWitt, David. Introduction to Heat Transfer. John Wiley and Sons, 1990. Classic heat transfer text with all the theory, equations and proper procedures an engineer needs to calculate thermal mass correctly.

2. Mills, A.F. Basic Heat and Mass Transfer. Irwin, 1995. Ditto.

3. 2005 ASHRAE Handbook: Fundamentals. Most of the principles and guidelines necessary to understand the ASHRAE Standards, but few of the essentials needed for a complete analysis.

Publisher’s Note:

See Chris Wark’s entire 7-part Green Roof Energy Series from 2010-2011 online and in PDF: “Cooler Than Cool Roofs: How Heat Doesn’t Move Through a Green Roof.“

Christopher G. Wark

Christopher Wark is Principal of Wark Energy Consulting and the founder of Ponix MicroAg LLC, a development-stage company that is creating a line of compact plant enclosures for the CEA market. Chris has over 30 years of multidisciplinary engineering experience providing mechanical, analytical, and electronics support and services to manufacturers, universities and national labs. He holds Bachelor and Master of Science degrees in Mechanical Engineering (with a minor in Materials Science) from Washington State University where his graduate work focused on thermodynamics, fluid dynamics, and combustion.

For the past 19 years, Chris has focused his efforts on the development and promotion of technical solutions in architecture and construction. He has provided energy and environmental quality analysis, CFD modeling, and LEED consulting services for several engineering and building consulting firms in New York and California. In 2002, Chris established SHADE Consulting/Green Roof Innovations (GRI) with his wife Wendy.

With GRI, Chris developed several innovative modular eco-roof systems and in 2010, Chris designed a modular planting system in partnership with Guiyang Chuangjia High-Tech Accelerator Co. LTD in Guiyang, China. In Guiyang, he saw how most of the apartment balconies and rooftops were filled with vegetable gardens. The idea of providing an improved environment for food production in built environments, along with key GRI design concepts, inspired the development of the patented pPod™ miniature greenhouse developed by Ponix MicroAg.

Contact Christopher Wark at: [email protected], 917-565-6919.

[ad_2]

Source link